Single Value SC3 AST Smart ECO VCM Modules Installation

The unit should be installed into an engine at ambient temperature so you do not get a check engine light and error code [P0118 or P0128]. Most engines will take 4+ hours to fully cool down to ambient temperature after being operated normally.

If you have an ODB2 scanner and can clear the engine codes, then it is OK to install with a warm engine, however please make sure it is cool enough to the touch so you do not burn your hands.

If you have an ODB2 scanner and can clear the engine codes, then it is OK to install with a warm engine, however please make sure it is cool enough to the touch so you do not burn your hands.

STEP 1: FAMILIARIZE YOURSELF WITH THE PRODUCT AND ENGINE BAY

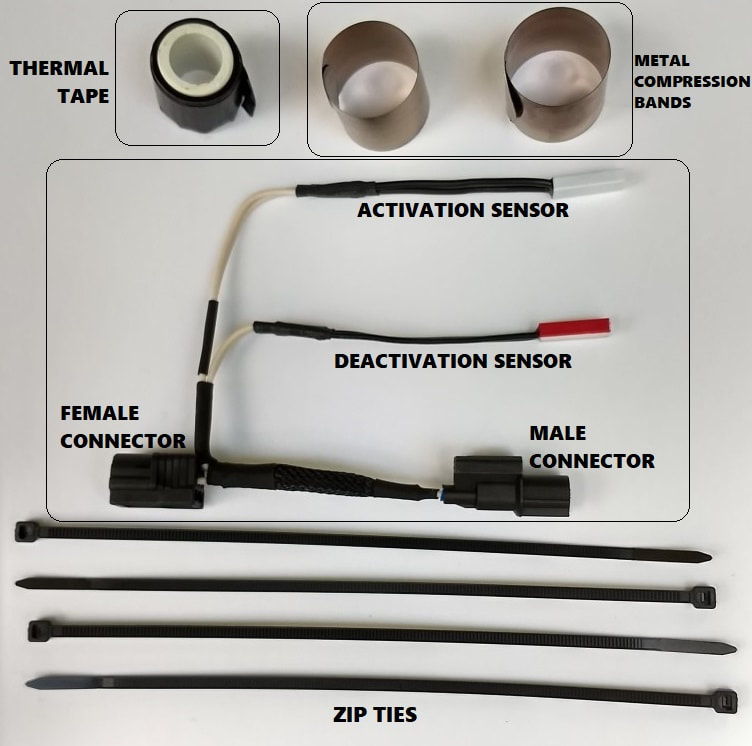

This unit comes standard with several mounting supplies. Your actual unit may differ slightly from the photo.

1 - Roll of Thermal Tape

2 - Metal Compression Bands

1 - VCM Disabling device with dual sensors [longer wire is the ACTIVATION sensor, shorter wire is the DEACTIVATION sensor]

4 - Plastic Zip Ties

This unit comes standard with several mounting supplies. Your actual unit may differ slightly from the photo.

1 - Roll of Thermal Tape

2 - Metal Compression Bands

1 - VCM Disabling device with dual sensors [longer wire is the ACTIVATION sensor, shorter wire is the DEACTIVATION sensor]

4 - Plastic Zip Ties

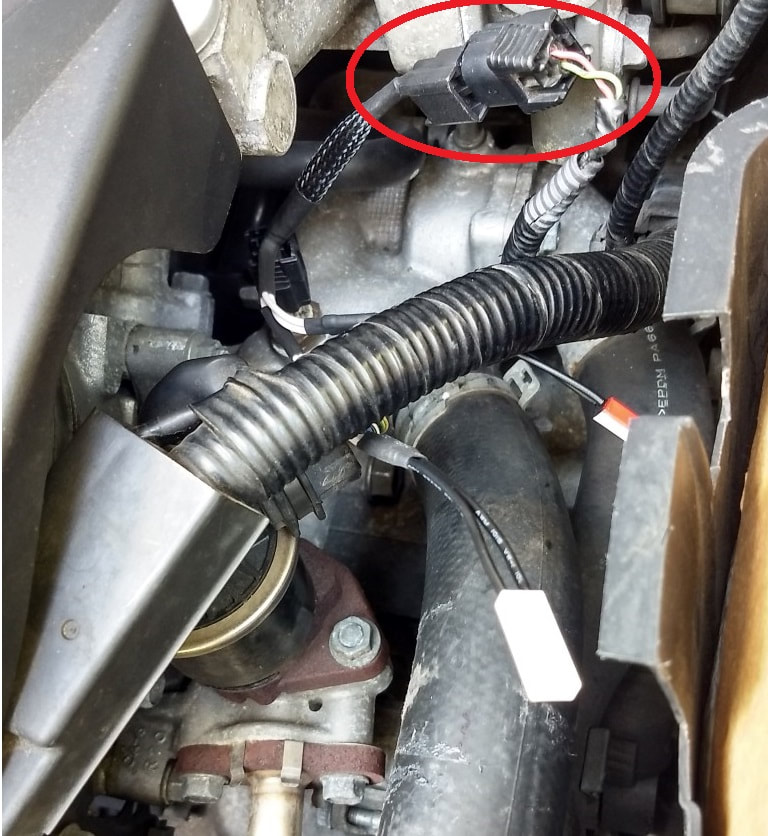

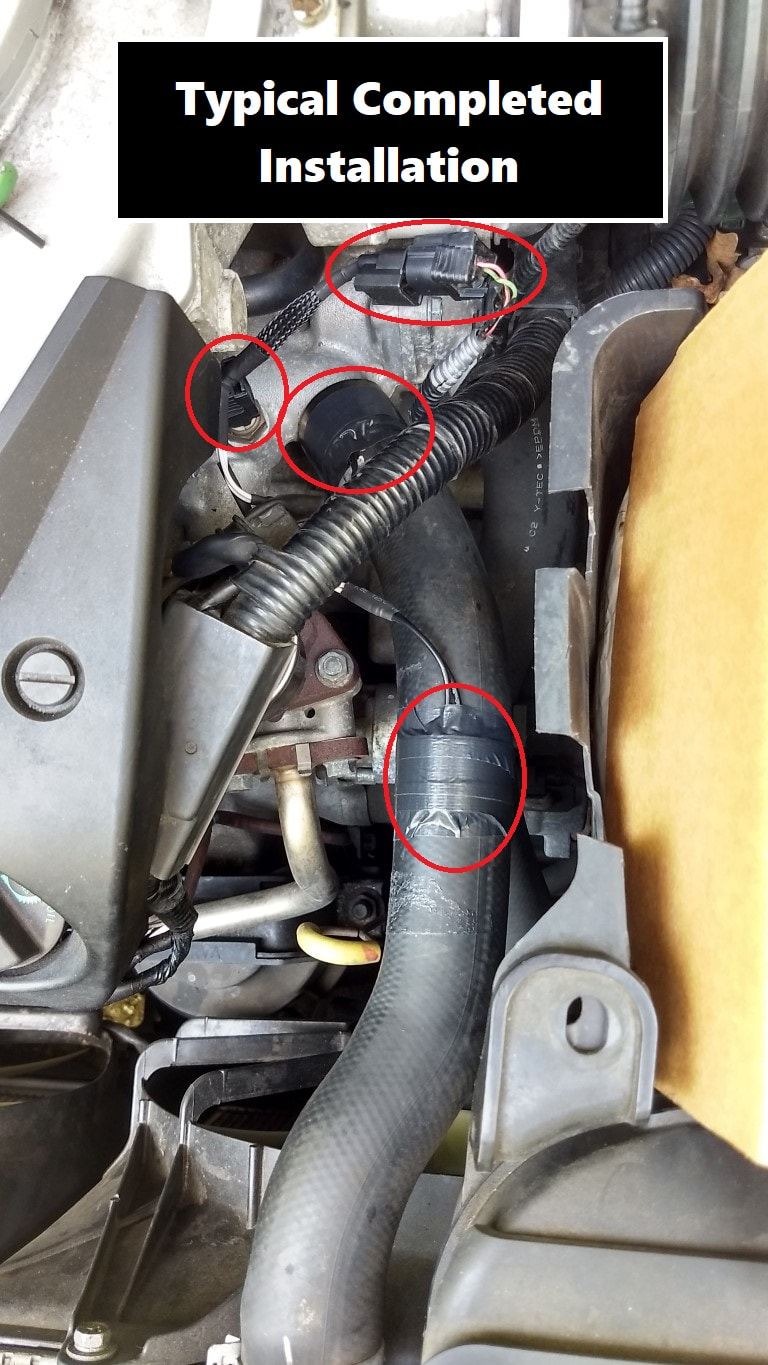

We will be working on the right side of the engine, near connector ECT1 [circled below]

STEP 2: REMOVE EXISTING PLUG

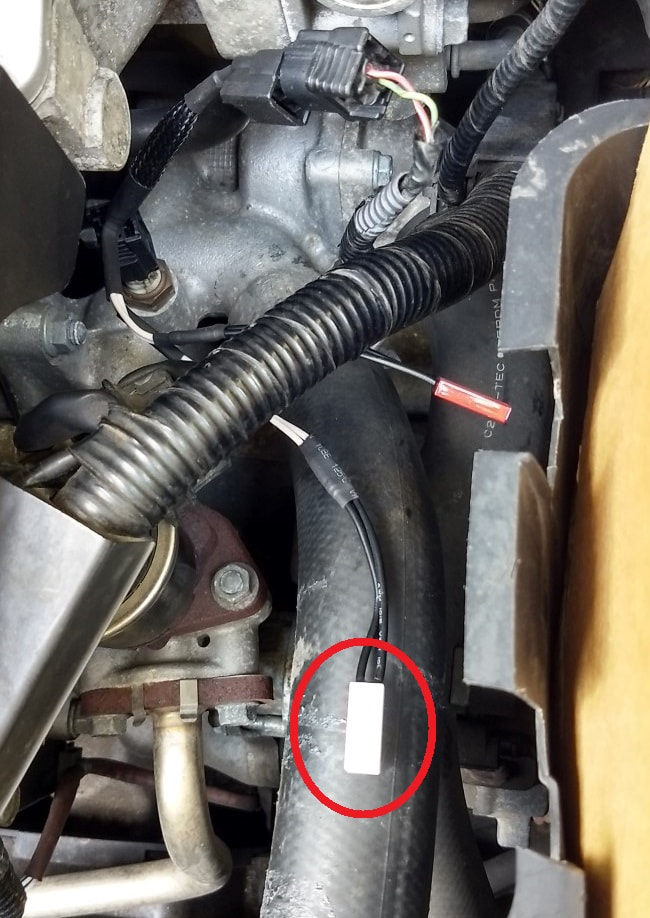

The plug has a locking mechanism on one side, push in with your thumb to unlock it, then carefully slide it up to remove the female plug from the ECT1 sensor. In the photo below, you can see the female plug fully removed from the ECT1 sensor.

The plug has a locking mechanism on one side, push in with your thumb to unlock it, then carefully slide it up to remove the female plug from the ECT1 sensor. In the photo below, you can see the female plug fully removed from the ECT1 sensor.

STEP 3: PLUG THE MODULE IN

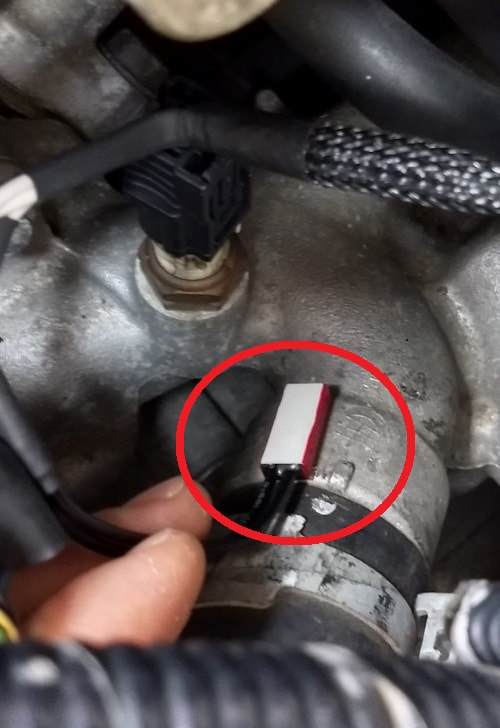

Plug the smaller connector of the AST Smart ECO VCM disabling device into white connector in the engine, then plug the larger connector into the plug you just removed from the car.

Plug the smaller connector of the AST Smart ECO VCM disabling device into white connector in the engine, then plug the larger connector into the plug you just removed from the car.

STEP 4: ATTACH ACTIVATION SENSOR [LONG LEADS] TO RADIATOR UPPER HOSE

Lay the ACTIVATION sensor [longer leads] flat onto the radiator hose, then cover with a metal thermal band.

Be careful with the band, it snaps shut quickly.

Lay the ACTIVATION sensor [longer leads] flat onto the radiator hose, then cover with a metal thermal band.

Be careful with the band, it snaps shut quickly.

STEP 5: ATTACH ENGINE OVERHEAT SENSOR [SHORT LEADS, RED MARKING] TO METAL PIPE

Lay the DEACTIVATION sensor [shorter leads, red stripe on sensor] flat onto the metal pipe at the end of the radiator hose, then cover with a metal thermal band.

Lay the DEACTIVATION sensor [shorter leads, red stripe on sensor] flat onto the metal pipe at the end of the radiator hose, then cover with a metal thermal band.

STEP 6: [OPTIONAL] COVER THE BANDS WITH ZIP TIES AND / OR THERMAL TAPE

It is important to make sure the DEACTIVATION sensor receives heat quickly from the engine to operate properly.

The engine overheat sensor [installed on step 5] can be further secured with a zip tie or thermal tape - or both.

The more it is insulated / attached to the pipe, the faster it will respond to an engine overheat scenario and disable the unit.

The photos below show it covered with thermal tape [left] or a zip tie [right]

It is important to make sure the DEACTIVATION sensor receives heat quickly from the engine to operate properly.

The engine overheat sensor [installed on step 5] can be further secured with a zip tie or thermal tape - or both.

The more it is insulated / attached to the pipe, the faster it will respond to an engine overheat scenario and disable the unit.

The photos below show it covered with thermal tape [left] or a zip tie [right]

STEP 7: TEST DRIVE THE VEHICLE

The unit will remain inactive until heat from the radiator warms up the activation sensor tied to the upper radiator hose.

Generally this will engage the unit at approximately 115F - 125F, or about 5-10 minutes after starting the vehicle.

During this time, the ECO light may still come on but this is normal and by design. Other companies VCM disabling devices have to use a very small adjustment because they are 'always on' and the computer will process an error if the adjustment is too high.

The AST Smart ECO VCM module is able to use a large adjustment to help keep ECO off more due to the build in delayed activation.

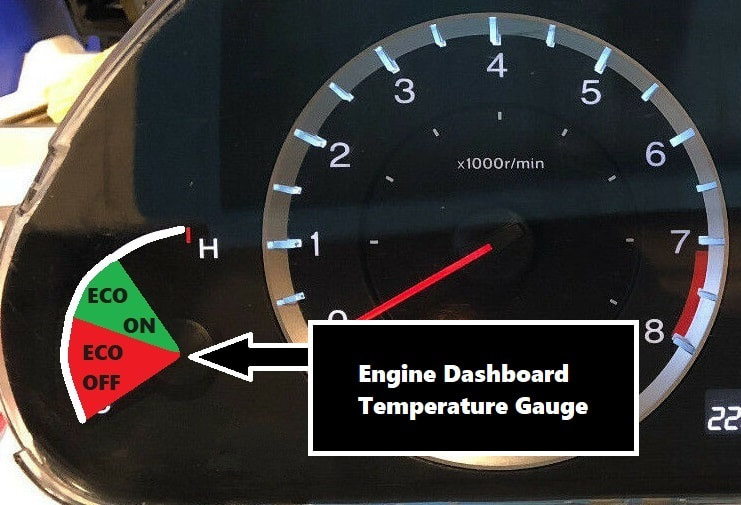

Once the car is started, you should notice the temperature gauge on the dashboard raise slowly like normal. When the VCM disabling device turns on, the gauge will drop down slightly into the "ECO OFF" ranged noted in the picture.

If you feel the unit is taking too long to activate, you can move the ACTIVATION sensor closer to the engine so it receives heat faster. Alternately, you can use the thermal tape to cover the metal compression band so the heat from the hose does not radiate away into the engine bay. [Photos Below] Most installations work well with the thermal tape, and if you live in a very hot area like south Texas or Florida, you can likely just use the metal compression band without the tape.

The unit will remain inactive until heat from the radiator warms up the activation sensor tied to the upper radiator hose.

Generally this will engage the unit at approximately 115F - 125F, or about 5-10 minutes after starting the vehicle.

During this time, the ECO light may still come on but this is normal and by design. Other companies VCM disabling devices have to use a very small adjustment because they are 'always on' and the computer will process an error if the adjustment is too high.

The AST Smart ECO VCM module is able to use a large adjustment to help keep ECO off more due to the build in delayed activation.

Once the car is started, you should notice the temperature gauge on the dashboard raise slowly like normal. When the VCM disabling device turns on, the gauge will drop down slightly into the "ECO OFF" ranged noted in the picture.

If you feel the unit is taking too long to activate, you can move the ACTIVATION sensor closer to the engine so it receives heat faster. Alternately, you can use the thermal tape to cover the metal compression band so the heat from the hose does not radiate away into the engine bay. [Photos Below] Most installations work well with the thermal tape, and if you live in a very hot area like south Texas or Florida, you can likely just use the metal compression band without the tape.

STEP 8: SECURE ANY LOOSE WIRES AND ENJOY YOUR NEW ENGINE

Some vehicles may have more slack wires than others - secure any loose wires and try to prevent anything from touching the engine that is not insulated.

This completes the installation of the unit.

All items are 100% tested and inspected prior to shipping.

Feel free to contact us with any questions / comments / concerns you may have, or technical support you require.

We can quickly diagnose most installation problems you may have.

Email: [email protected]

Phone: 209-353-3330

Some vehicles may have more slack wires than others - secure any loose wires and try to prevent anything from touching the engine that is not insulated.

This completes the installation of the unit.

All items are 100% tested and inspected prior to shipping.

Feel free to contact us with any questions / comments / concerns you may have, or technical support you require.

We can quickly diagnose most installation problems you may have.

Email: [email protected]

Phone: 209-353-3330

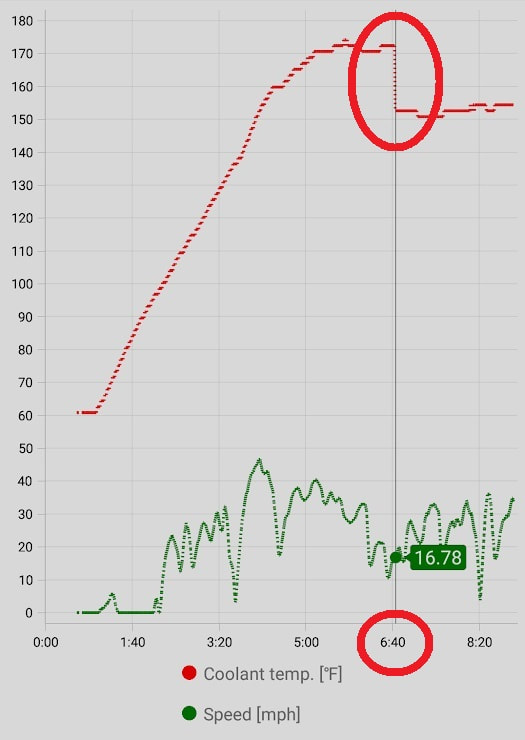

RECORDED DATA FROM A TYPICAL DRIVE:

The graph below shows a typical unit in operation, reflecting data I collected from my ODB2 scanner and smartphone.

The engine temperature was approximately 63F when first started. This was also the air temperature outside.

I backed down my driveway and left the car to idle for approximately 1 minute, as I had to run back into the house to grab a couple of things for the road :) [I almost forgot my coffee!]

I then proceeded to leave my development and drive on some 25, 35 and 40 mph roads.

The engine temperature slowly increased until about 172F.

At that point, their was enough heat to transfer over to the AST Smart ECO VCM modules thermal switch and activate the unit.

The ECT1 reported engine temperature dropped by approximately 20 degrees to 152F.

While the engine temperature was being reported below 167F, the ECO mode was disabled.

Their was a small window from 5 minutes to 6:40 where the ECO mode was engaging, however the delayed activation of the AST Smart ECO VCM module is what sets it apart from the competitors - it automatically activates when the engine has warmed up, helping to prevent P0118 and P0128 check engine lights that other, "always on" units experience.

The graph below shows a typical unit in operation, reflecting data I collected from my ODB2 scanner and smartphone.

The engine temperature was approximately 63F when first started. This was also the air temperature outside.

I backed down my driveway and left the car to idle for approximately 1 minute, as I had to run back into the house to grab a couple of things for the road :) [I almost forgot my coffee!]

I then proceeded to leave my development and drive on some 25, 35 and 40 mph roads.

The engine temperature slowly increased until about 172F.

At that point, their was enough heat to transfer over to the AST Smart ECO VCM modules thermal switch and activate the unit.

The ECT1 reported engine temperature dropped by approximately 20 degrees to 152F.

While the engine temperature was being reported below 167F, the ECO mode was disabled.

Their was a small window from 5 minutes to 6:40 where the ECO mode was engaging, however the delayed activation of the AST Smart ECO VCM module is what sets it apart from the competitors - it automatically activates when the engine has warmed up, helping to prevent P0118 and P0128 check engine lights that other, "always on" units experience.